NEW Suppliers

UK SMEUNITE®

SMEUNITE® is a Lockheed Martin UK designed supplier ecosystem for Small and Medium Enterprises (SMEs) that will offer a collaborative technical community to support emerging and future requirements.

Lockheed Martin UK and Our Suppliers

Lockheed Martin UK delivers capabilities to organisations operating in several key sectors. These include aerospace, cyber security, defence, energy, public services and transport.

We work closely with academic institutions, commercial airports, energy companies, government departments, health services, the military, Royal Mail, public sector bodies, transport solution providers and utilities to support their work of national importance, day in and day out.

Lockheed Martin UK works closely with a broad range of suppliers from around the UK to deliver the best programmes and systems to enable these organisations of critical national importance to do their jobs effectively, day in and day out.

Lockheed Martin UK currently works with approximately 1,000 suppliers around the UK, 75% of which are SMEs. Over the last five years (2013-2017) the company committed approximately £1.4B with the UK supply chain.

Good partnerships between Lockheed Martin and its suppliers are the cornerstone of its ability to deliver unique capabilities to our valued customers, whether it’s helping to deliver F-35 to 12 nations around the world or 50 million items of post to individuals around the UK every day.

Lockheed Martin UK and its suppliers must deliver innovative products and services to enable these organisations of critical national importance to do their jobs effectively.

To ensure this continues to happen, we are working to create more collaborative relationships, make our business more agile and lean, and ensure a better return on invested capital for all partners.

Our aim is to nurture suppliers without threatening their intellectual property or business interests. If we manage to achieve this together, greater international business opportunities can result for all.

We are taking practical approaches to making it easier for suppliers, current and new, to work more effectively with us. One example is our newly established supplier financing initiative. This means of reducing risk is only one of many ways we hope to support our suppliers better when they work for us.

These web pages also contain information about our unique proposition to suppliers all over the UK.

We hope this section of our website will help you learn more about how to do business with Lockheed Martin UK as we enter new sectors and markets together. We would also be interested to hear from you.

If you are interested in finding out more about our global supply chain, click here.

What We Buy

If you are a supplier of one or more of these commodities, we invite you to get in touch.

Please submit relevant marketing details and contact information to supply.lmuk@lmco.com.

Manufacturing & Engineering

- Machining & Fabrication

Sheet Metal

- Assembly

- Engineering & Technical Services

Special Processes

- Chemical Processing - Electroplating, Anodising & Painting

Composites - Heat Treating

- Measurement, Inspection, Testing & Calibration

- Nonconventional Machining & Surface Enhancement

- Material Testing

- Non Destructive Testing

- Printed Circuit Board Manufacture & Assembly

- Welding

Electronics

- Contract Electronics Manufacturing Services

- Cable Assemblies & Connectors

- Electronic Components & Equipment

Business Supplies

- Office Supplies & Equipment

- General Consumables

- Telecommunications

- IT Equipment, Software & Services

Facility Support Services

- Air Conditioning Services

- Building, Infrastructure & Installation Services Electricians

- Painters

- Gardening Services

- Maintenance Services

Service Providers

- Audit & Assessment Services

- Education & Training Provision Staffing

- Marketing & Promotional Services

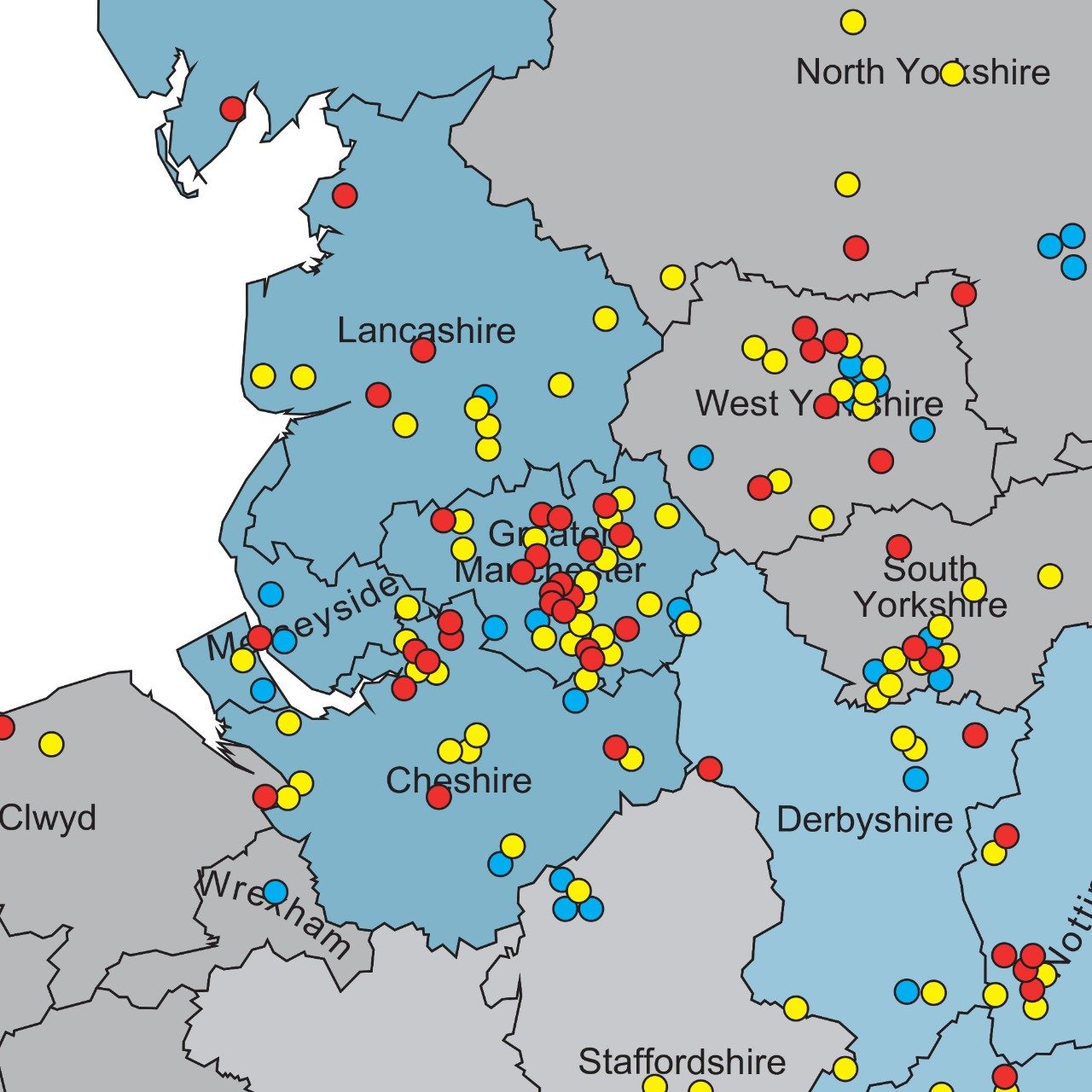

Supplier Facts and Figures

- 1,000 suppliers

- 75% are Small and Medium Enterprises (SMEs)

- 10,000 jobs sustained

- Jobs in every region of the UK

Locations of Our Supply Chain Partner Companies

How to Become a Supplier

As a supplier to Lockheed Martin UK, your relationship with us will not simply be one where you manufacture a product and we buy it. It is a true partnership where each partner supports the other in achieving excellence for customers.

The rewards can be significant. As well as the obvious satisfactions of increased revenue and the opportunity to grow business, your company will benefit from a close relationship with Lockheed Martin UK in many ways. Having our experts work side by side with your team means both organisations learn from each other and build mutual respect which is fundamental to strong long-term relationships.

Working with Lockheed Martin here in the UK can also open the door to overseas business thanks to our international footprint.

Our business environment is highly competitive and so Lockheed Martin UK is seeking suppliers who demonstrate a commitment to continuous improvement, innovation and who can deliver programmes and products better, faster and smarter.

To become a supplier to Lockheed Martin you must become familiar with our products and services. Knowing what we produce, purchase, and our areas of immediate need will help you evaluate opportunities and understand our requirements.

The next step is to make us aware of your capabilities. Please see the Who to contact page.

Please note: Suppliers are selected based on a company's ability to satisfy Lockheed Martin UK’s requirements, including quality, price, delivery and continuity of supply, capacity and reliability. Although Lockheed Martin has a strong base of suppliers, it is a competitive business environment and at times there may not be an immediate opportunity.

Lockheed Martin UK takes it responsibilities to its customers very seriously. Therefore, in order to become a supplier to Lockheed Martin UK you will be asked to comply with cyber security requirements and a Code of Conduct.

Our UK Supplier Policies & Guidance

Goods and services provided by our suppliers have a key impact on the quality of the products, solutions and services we offer our customers. To maintain a high level of quality, we are determined to establish and maintain close and long-lasting relationships with our suppliers. Any questions can be sent to supply.lmuk@lmco.com

Current versions of the Quality Requirements & Guidance for Suppliers and Potential Suppliers to our Ampthill Site, Bedfordshire:

- QM003 Quality Requirements for Suppliers reflect the quality flow down requirements of LMUK customers. Archived copies of previous version of QM003 are available below.

- SQAG001 First Article Inspection Guide provides directions on how to identify, plan for and satisfy Lockheed Martin UK Ampthill specific requirements for completing a compliant First Article Inspection (FAI). It is based on the latest revision of AS9102 and overall LMUK expectations.

- SPG01 Special Processes Guidebook provides further information on special processes.

- RCCA – Root Cause Corrective Action Problem Solving Guidebook sets out the steps that should be taken using the 8D methodology when problem solving with root cause corrective action.

- F0389 Deliverable Quality Plan Template is an optional form to assist suppliers in presenting a detailed quality plan on how the supplier intends to meet the QM003 requirements.

- F0577 Supplier Deviation Request form is an optional form to assist suppliers requesting a production permit or concession in accordance with QM003.

- 1QA734-D01 LMUK Ampthill Foreign Object Damage Prevention is the LMUK Ampthill policy on FOD prevention. It can be used by our suppliers as a source of information and best practice around preventing FOD in their deliverables to Ampthill.

Lockheed Martin Engineering Materials Database

Lockheed Martin UK – Ampthill have developed Classification Codes for various materials. For more information and guidance see the LMUK Ampthill Materials Database Guide.

LMUK Ampthill Engineering Materials Database identifies material classifications and acceptable alternatives for use only where a material classification group is specified on Lockheed Martin drawing. Refer to guidance document for further information.

LMUK Ampthill Materials Database Archives

- Version 7 - 01/06/2023

- Version 6 - 01/09/2022

- Version 5 - 22/09/2021

- Version 4 - 12/05/2021

- Version 3 - 28/10/2020

- Version 2 - 03/09/2020

- Version 1 - 23/08/2020

Counterfeit and fraudulent items

There is large, profitable and growing capability by unscrupulous organisations to counterfeit or fraudulently produce and sell aerospace & defence grade components and materials as genuine.

The world-wide trade in these illegal items is worth £ multi-millions per annum with a large proportion originating from the Far East.

Manufacturers of aerospace & defence equipment are increasingly at risk of unwittingly embodying these counterfeit or fraudulent items into their deliverable products with potentially catastrophic consequences.

This risk has the potential to manifest at any point in the supply chain so Lockheed Martin demands equal vigilance from their sub-tiers throughout the supply chain in avoiding and detecting all items that are not genuine.

Definitions

Counterfeit Item: An item confirmed to be a copy, imitation or substitute that has been represented, identified, or marked as genuine, and/or altered without legal right with intent to deceive or defraud.

Fraudulent Item: Any item misrepresented to the customer as meeting the customer’s requirements.

10 Warning Signs

Be suspicious of counterfeit and fraudulent items if you encounter any of the following warning signs:

1) |

Identification Markings |

Alterations, wrong size, location, marking method incorrect, smudged or blurred, lot or batch numbers missing, incorrect suppliers logo |

2) |

Product Condition |

Resurfaced / refinished, evidence of re-work, wrong colour, shape or size, evidence or previous use (used item) |

3) |

Paperwork / Certificate of Conformity |

Accompanying paperwork has poor spelling or grammar, errors or evidence of tampering, missing information or does not relate to the delivered product |

4) |

Lot Information |

Unusual serialisation or reference numbers, lot information missing |

5) |

Chain of Ownership |

Unverifiable traceability to source |

6) |

Unusual Location |

Items delivered from a location differing from previous or from prohibited countries |

7) |

Low Price |

A price significantly lower than historical pricing data or market norm |

8) |

Availability |

Obsolete or scarce items suddenly becoming available |

9) |

OEM Certification |

Unavailable OEM certification or uncertified OEM |

10) |

Unfamiliar Supplier |

Supplier or agent / stockist not known or previously used |

Further Assistance

For further assistance or to report suspected counterfeit parts, contact the Quality Manager at the Lockheed Martin UK division you are contracted to supply or Konrad Burgoyne.

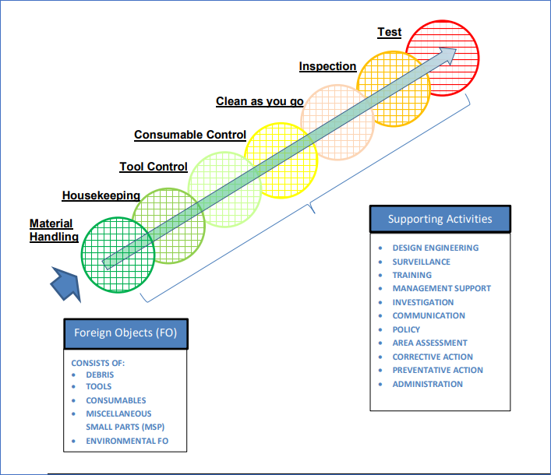

FOD Prevention

In the aerospace and defence industry, Foreign Object Damage (FOD) costs billions in the form of schedule delays, rework, injuries, and product losses – a bit of debris lodged in the right place could be enough to drop an aircraft right out of the sky. The full impact of FOD is difficult to measure, as often times FOD will cause other defects/damage as it migrates within an assembly, creating additional costs that may not be captured. Ultimately, the biggest cost of FOD is your company’s reputation – delivering products that are not FOD-free sends the message that you do not have control over your manufacturing processes or that you don’t care about the product’s performance.

A Foreign Object is a substance or article alien to a product or system that may or may not cause Foreign Object Damage if not removed or controlled and allowed to migrate onto the product, system, or introduced into an operational environment

Ampthill’s FOD Policy is a detailed breakout for preventing FOD during fabrication, manufacturing, modification and test. Successful FOD prevention in this environment relies on the proper assessment of FOD risk combined with the appropriate controls to mitigate the risk. As no single process is expected to be 100% effective at eliminating the risk of FOD, LMUK Ampthill employs a layered approach designed to progressively reduce the presence of Foreign Objects to mitigate the risk of FOD as shown:

Further Assistance

For further assistance on preventing FOD, contact the Quality Manager at the Lockheed Martin UK division you are contracted to supply, or Konrad Burgoyne

Cybersecurity

Cyber security attacks continue to increase in frequency and sophistication for the aerospace & defence industry. Adversaries are targeting anyone who possesses sensitive information, including the government, industry leaders and suppliers. It is imperative that our suppliers understand what’s at stake and recognise our shared role in protecting sensitive information and intellectual property. A single mistake or breach could have enormous consequences for our customers, our business, the aerospace & defence industry, and national security.

Understanding a supplier’s ability to protect sensitive information and manage cyber security risk is important to Lockheed Martin and helps us make decisions on how best to manage risk. We use a variety of methods such as supplier briefings, assessments, information sharing sessions, and the supplier cyber security questionnaire to understand a supplier’s cyber security readiness.

All suppliers where there is a need to share Sensitive Data with or where a denial of service due to a cyber incident will be required to hold as a minimum to be accredited to CES (Cyber Essential Scheme). The CES certification is the minimum standard and in many cases controls over and above will likely be required.